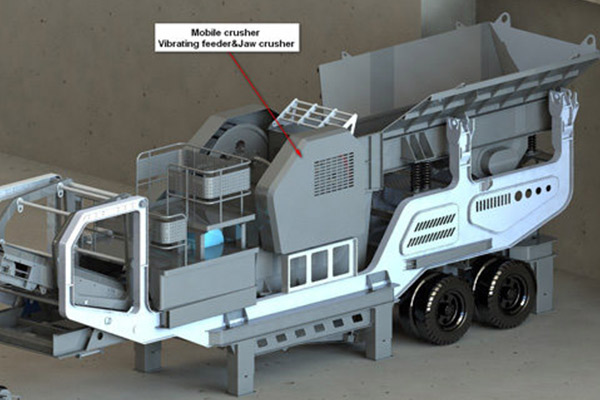

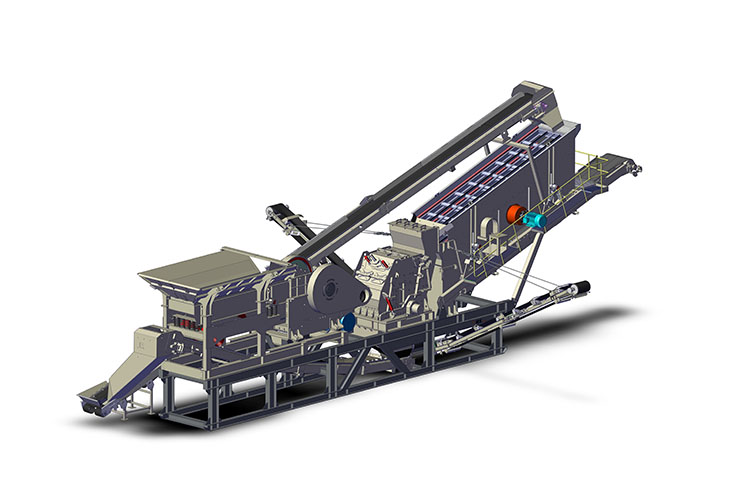

A mobile crushing station is a versatile piece of equipment that integrates crushing, screening, and conveying functions, widely used in mining, construction waste processing, and other fields. With the advent of Industry 4.0, intelligent technology has become a key driver in the evolution of mobile crushing stations. This article explores the application of intelligent technologies in mobile crushing stations and their tangible benefits.

Intelligent Technologies

1. Automated Control Systems

Modern mobile crushing stations commonly employ PLC (Programmable Logic Controller) systems to enable automated operation. Remote monitoring technology allows operators to oversee equipment status from a control room in real time, minimizing on-site manual intervention. For instance, certain models allow operators to adjust crushing parameters via a touchscreen, significantly enhancing operational efficiency.

2. Smart Sensing Technology

Pressure, temperature, and vibration sensors are widely integrated into mobile crushing stations to monitor operational conditions. For example, vibration sensors can detect the load in the crushing chamber in real time, preventing equipment damage due to overloading. This data also supports predictive maintenance, extending the equipment’s service life.

3. AI Algorithm Optimization

Machine learning algorithms enable mobile crushing stations to automatically optimize crushing parameters based on material properties. For instance, when processing high-hardness ores, the system can adjust the crusher’s speed and feed rate to boost output while reducing energy consumption.

Application Cases

1. Mining Operations

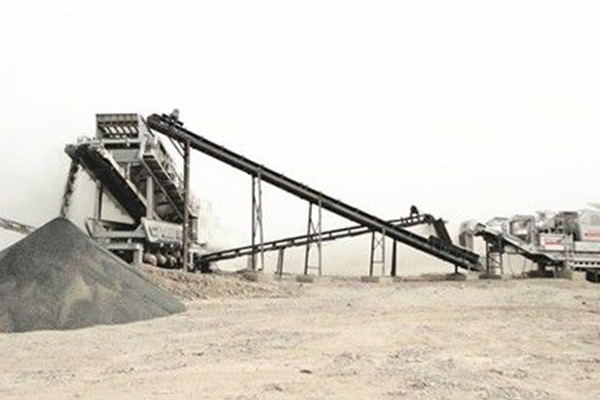

In a large open-pit coal mine, a mobile crushing station equipped with an intelligent system increased production efficiency by 20%. Through remote monitoring and automated adjustments, the equipment maintained stable performance in harsh conditions while reducing safety risks for operators.

2. Construction Waste Processing

In an urban construction waste recycling project, an intelligent mobile crushing station utilized sensors to monitor dust and noise levels. Paired with an efficient dust suppression system, it achieved a resource recovery rate of over 85% while complying with stringent environmental regulations.

Future Outlook

With the development of 5G and IoT technologies, mobile crushing stations are poised to achieve greater interconnectivity. Real-time data transmission and cloud-based analytics will further enhance equipment performance, driving the industry toward greater intelligence and digitization.

Intelligent technologies not only improve the efficiency and safety of mobile crushing stations but also enable their application in diverse scenarios. This trend will continue to shape the industry’s future.