Accelerated Construction Waste Recycling Drives the Popularization of Mobile Crushing and Screening Stations

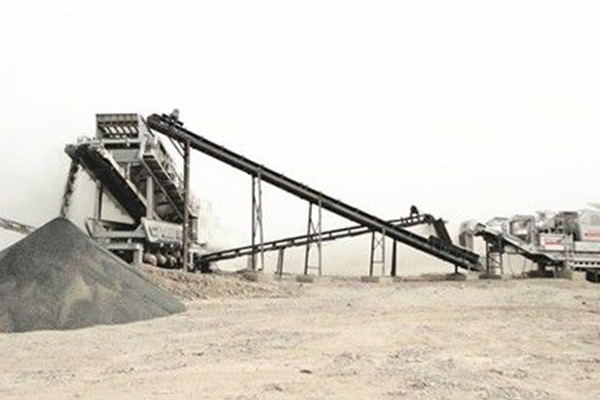

With the acceleration of urbanization, the generation of large amounts of construction waste has become a significant challenge. Traditional methods of construction waste disposal, such as landfilling or incineration, not only consume land resources but also cause environmental pollution. In recent years, the resource utilization of construction waste has become a global consensus, and the application of mobile crushing and screening stations aligns perfectly with this trend, enabling the efficient recycling of materials such as discarded concrete, bricks, and steel.

High Mobility Adapts to Variable Working Conditions

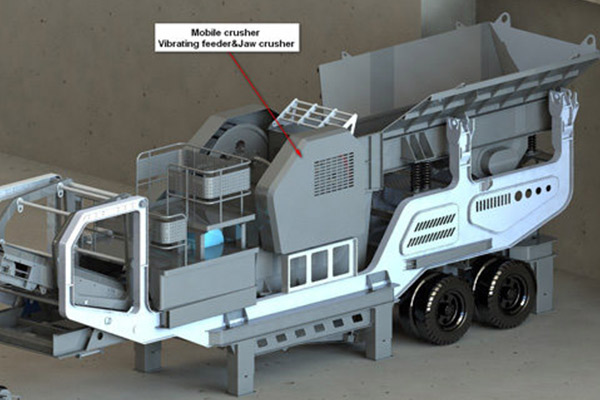

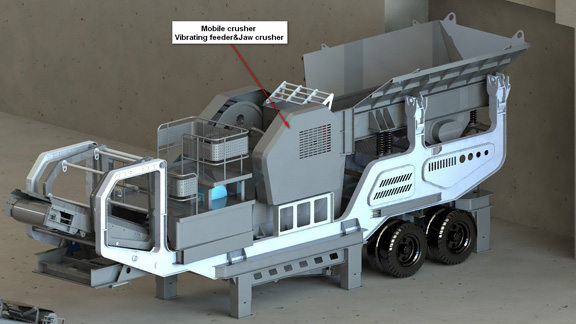

Unlike fixed crushing equipment, mobile crushing and screening stations do not require additional infrastructure and can be flexibly moved to construction sites for direct operation. This reduces material transportation costs and improves processing efficiency. Their crawler or tire designs allow them to adapt to various terrains, whether at demolition sites, mining areas, or along highways and railways, delivering efficient crushing and screening performance.

Intelligent Management Reduces Operating Costs

Modern mobile crushing and screening stations are generally equipped with intelligent control systems, enabling remote monitoring and operation. Operators can adjust equipment parameters in real-time via mobile terminals or control rooms to optimize production efficiency. Additionally, the built-in intelligent fault diagnosis function can provide early warnings for abnormal conditions, reducing downtime and extending equipment lifespan. Through big data analysis, producers can also optimize maintenance plans, lowering long-term operating costs.

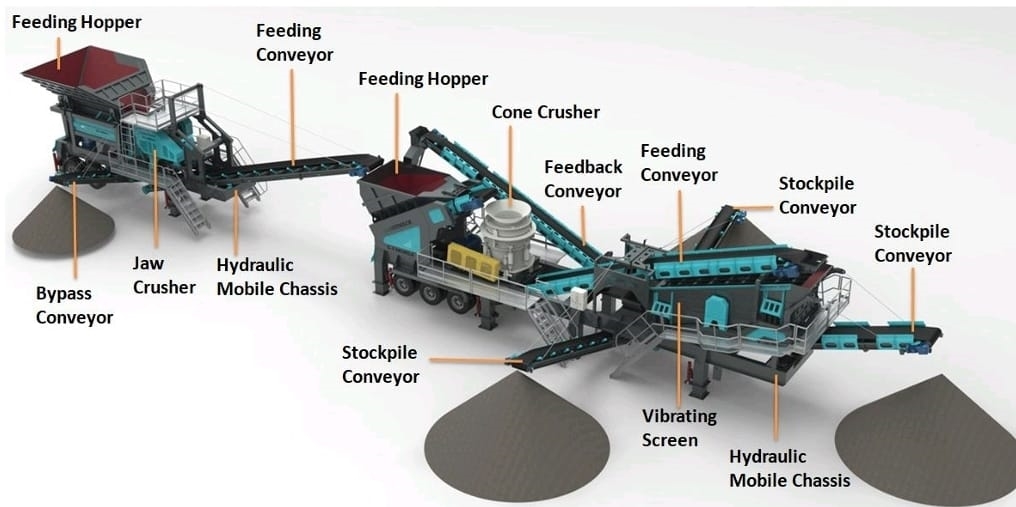

Diverse Configurations Meet Different Crushing Needs

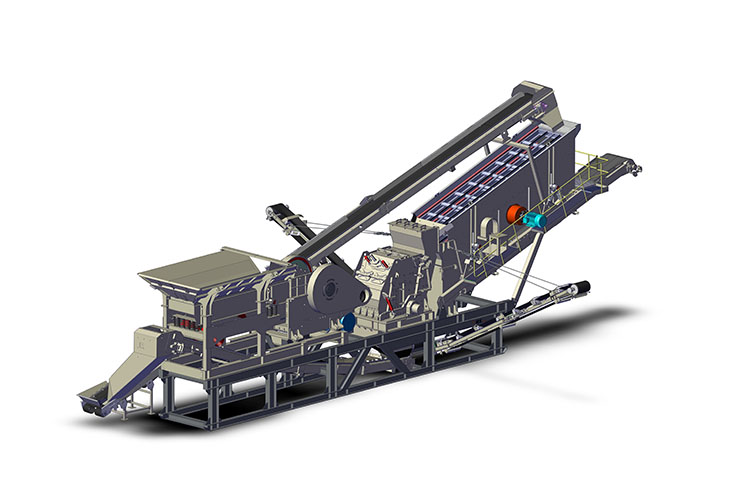

Depending on the application scenario, mobile crushing and screening stations can be configured with various crushing equipment, such as jaw crushers, cone crushers, and impact crushers, to meet different material crushing requirements. For example, in the mining industry, high-efficiency jaw crushers can be used for primary crushing, followed by cone crushers for secondary and fine crushing, improving ore processing efficiency. In the field of construction waste treatment, the combination of impact crushers and screening systems can better separate steel from concrete, enhancing the purity and quality of recycled aggregates.

Eco-Friendly and Energy-Saving Technologies Drive Industry Trends

Tightening environmental regulations have prompted companies to invest more in green production. The new generation of mobile crushing and screening stations adopts high-efficiency energy-saving motors and low-energy consumption crushing technologies, reducing overall energy consumption. Enclosed crushing chambers and efficient dust removal devices effectively minimize dust pollution, while noise suppression systems make the equipment more suitable for urban construction environments. Additionally, the use of recyclable wear-resistant materials enhances the sustainability and resource utilization of the equipment.

Automation, Intelligence, and Sustainable Development

In the future, mobile crushing and screening stations will develop towards higher efficiency, intelligence, and environmental friendliness. With the maturation of artificial intelligence, big data, and 5G IoT technologies, equipment will achieve remote operation, intelligent diagnosis, and automated maintenance, improving production efficiency and reducing manual intervention. Meanwhile, the continuous optimization of eco-friendly crushing and screening technologies will enable mobile stations to play a more significant role in resource recycling, infrastructure construction, and mining, driving the industry towards green, intelligent, and sustainable development.