Industry Demand and Challenges

Highway construction and urban redevelopment generate large amounts of construction waste while requiring significant quantities of aggregate materials. Traditional aggregate supply chains rely on fixed crushing plants, which entail high transportation costs and extended construction timelines. To address these challenges, the tyre-type mobile crushing and screening station has become an essential solution due to its efficiency, flexibility, and eco-friendly attributes in highway construction and construction waste recycling.

Equipment Features and Technological Advancements

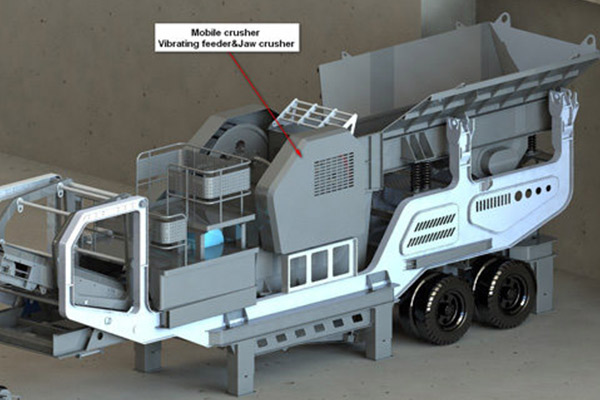

- Flexible Deployment: The tyre-type mobile crushing and screening station can be transported directly to construction sites, minimizing the need for long-distance waste transportation and reducing construction costs.

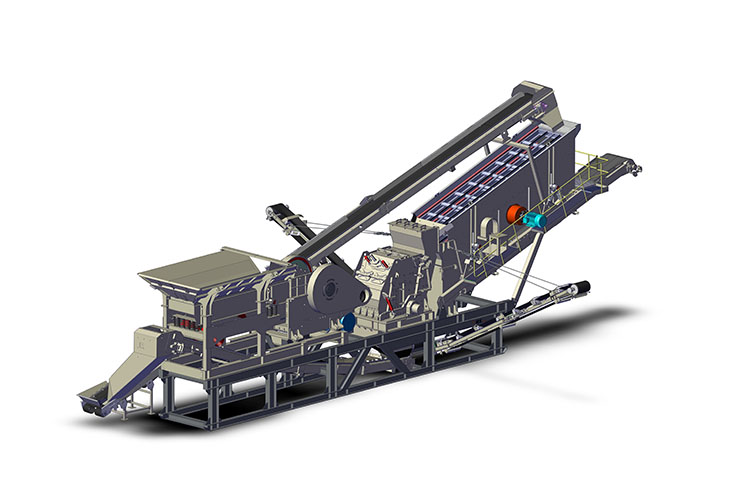

- Multi-Functional Integration: Combining crushing, screening, and conveying functions, it can be customized with different crushers to meet various processing requirements.

- Smart Operation: Equipped with a PLC automated control system, enabling remote monitoring and automatic adjustments, improving efficiency while reducing manual intervention.

- Eco-Friendly Design: Features high-efficiency dust suppression and noise reduction systems, minimizing environmental impact and lowering carbon emissions for sustainable production.

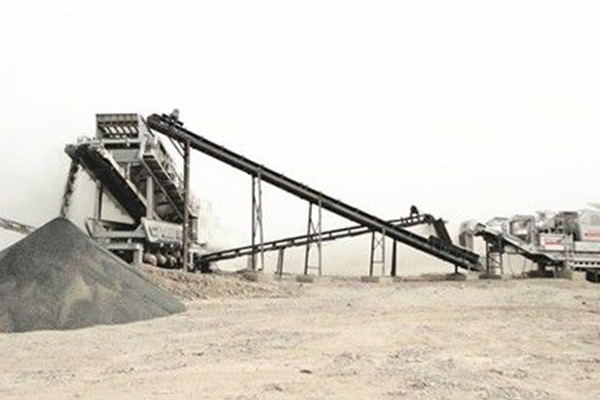

Highway Construction Project Case Study

In a highway expansion project, a tyre-type mobile crushing and screening station was deployed for on-site aggregate production. The equipment efficiently processed raw materials into various-sized crushed stones, directly used for road foundation and concrete production. This significantly improved construction efficiency, shortened project duration, and reduced procurement costs by recycling construction waste, achieving both economic and environmental benefits.

Future Development Trends

With increasing infrastructure demands and stricter environmental regulations, tyre-type mobile crushing and screening stations will continue to gain traction. Future developments will focus on enhanced automation, efficiency, and integration with IoT and big data technologies for remote management and intelligent operations, further optimizing work efficiency and resource utilization.